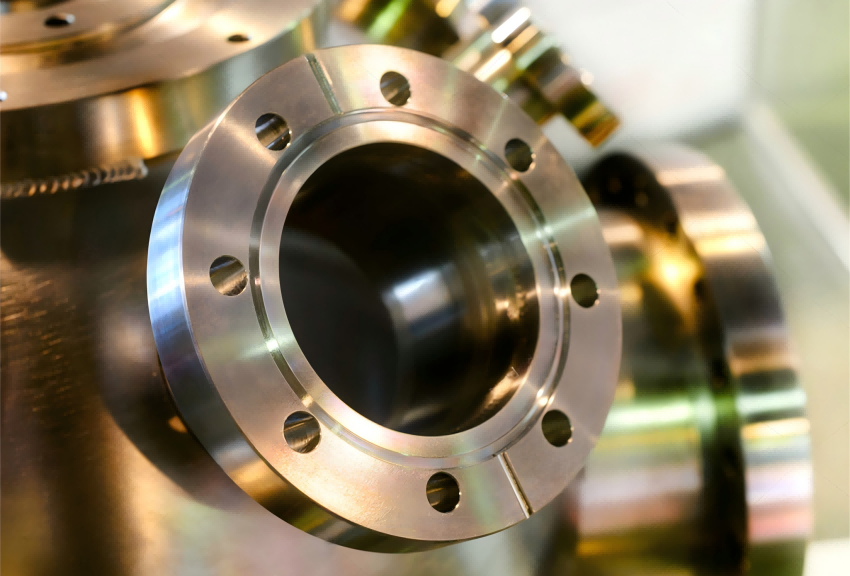

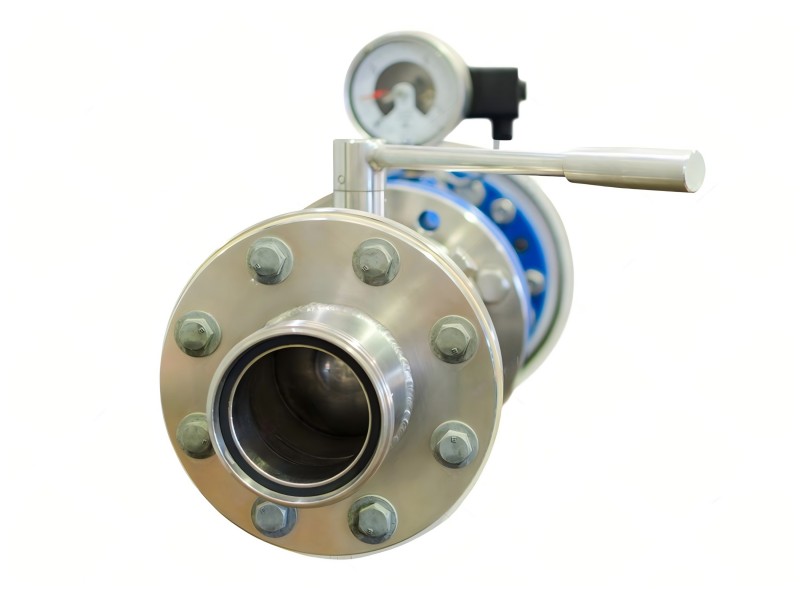

Pipe flanges are an integral part of many industrial processes, providing a robust and flexible connection for pipes, valves, pumps, and other equipment. They come in a variety of types, each with its own unique features, uses, and advantages. Here is a comprehensive guide to the ten most used pipe flanges:

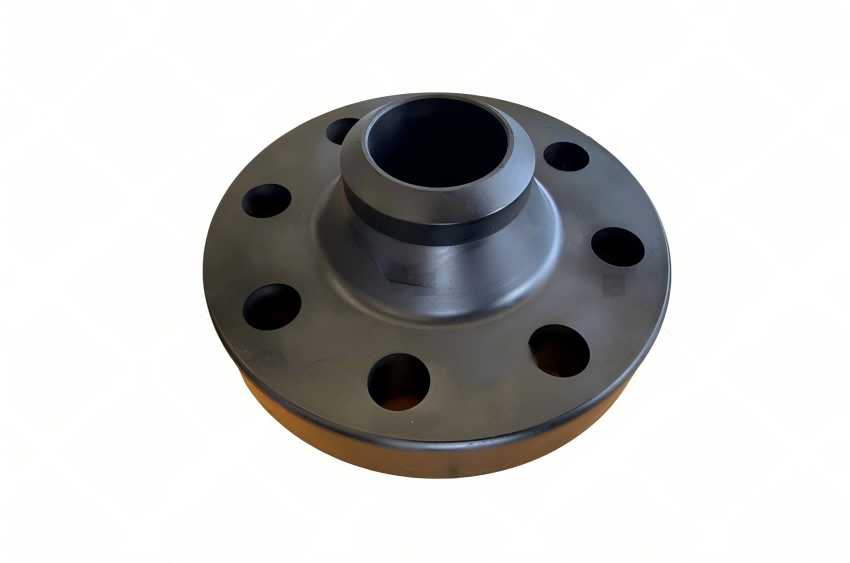

- Weld Neck Flanges: These flanges are distinguished by their protruding neck, which is welded to the pipe. The design creates a smooth and gradual transition that reduces stress concentrations and makes them ideal for high-pressure applications.

- Slip-On Flanges: As the name suggests, these flanges simply slip over the pipe. They are then welded both inside and outside to provide sufficient strength and prevent leakage. Slip-on flanges are cost-effective and easy to align.

- Blind Flanges: These are used to seal off a piping system or vessel opening. They have no bore and are commonly used for testing the flow of gas or liquid in a pipeline.

- Threaded Flanges: These flanges are similar to slip-on flanges but are threaded into the pipe. This eliminates the need for welding, making them ideal for extremely high-pressure applications.

- Socket Weld Flanges: Used for small pipe diameters, these flanges allow the pipe to be inserted into the socket of the flange before welding. This ensures high resistance to fatigue caused by bending stresses.

- Lap Joint Flanges: These flanges consist of two parts: a stub end and a loose backing flange. They are ideal for systems that require regular dismantling for inspection and cleaning.

- Orifice Flanges: These are used for measuring the flow rate of liquids or gases in a pipeline. They are essentially a pair of slip-on flanges with a hole in the center for an orifice plate.

Reducing Flanges: These flanges are used to connect pipes of different sizes. They eliminate the need for a reducer because one side of the flange is larger than the other.

Reducing Flanges: These flanges are used to connect pipes of different sizes. They eliminate the need for a reducer because one side of the flange is larger than the other.

- Long Weld Neck Flanges: Similar to weld neck flanges, these have a longer neck. They are often used in high-pressure applications where reinforcement is required.

- Expander Flanges: These are a cheaper (and lighter) alternative to using a separate reducer-welding neck flange combination. They are commonly used in offshore oil and gas pipelines.

In conclusion, pipe flanges play a critical role in various sectors, including oil and gas, petrochemicals, pharmaceuticals, and more. Understanding the differences between them can help choose the right flange for your specific application.

[Sources: Hardhat Engineer, Global Spec, Texas Flange, MachineMfg, Essentra Components, Dixon Valve, Tameson, Project Materials, Westermans, The Engineers Post]

#JSFITTINGS #RAYOUNG #STEELPIPE #FLANGE #STEELPIPE #MADEINCHINA #MANUFFACTURER #FACTORY #PIPEELBOW #PIPE REDUCER #INDUSTRYFLANGE

Email: admin@jsfittings.com

Whats App: 008618003119682