The production process of hot pushed seamless elbows is a fascinating blend of heat and mechanical force. The process begins with a seamless steel pipe, which is then subjected to heat and pressure to transform it into the desired elbow shape.

One commonly used method for manufacturing these elbows is the mandrel method or hot forming. In this process, the raw material, usually a pipe, is heated and then pushed over a tool known as a mandrel. This allows the pipe to expand and bend simultaneously, forming the elbow. This method is highly versatile and can be applied to a wide size range.

Another prevalent method involves hot pushing, stamping, and extrusion. Hot pushing is exactly what it sounds like – the pipe is heated and then physically pushed into the elbow shape. Stamping involves applying extreme force to the pipe to create the desired shape, while extrusion pushes the pipe through a shaped die to form the elbow.

What’s incredible about these processes is that they leave no seam on the elbow body, hence the term ‘seamless’. This lack of seam results in a stronger, more resilient fitting that’s less likely to leak or fail under pressure.

It’s also worth noting that there are two main types of seamless elbows – hot-rolled (extruded) and cold-drawn. As their names suggest, hot-rolled elbows are formed using heat, while cold-drawn elbows are made at room temperature. Both types have their own unique advantages and are used in different applications.

In conclusion, the production of hot-pushed seamless elbows is a sophisticated process that combines advanced manufacturing techniques with high-quality materials. Whether they’re made through hot forming, stamping, or extrusion, these seamless elbows play a crucial role in various industries, from oil and gas to construction and beyond.

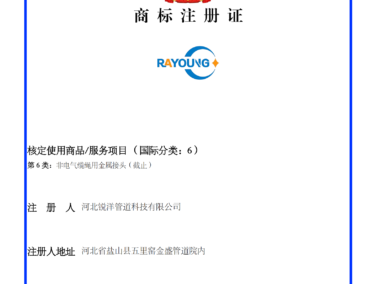

#JSFITTINGS #RAYOUNG #STEELPIPE #FLANGE #STEELPIPE #MADEINCHINA #MANUFFACTURER #FACTORY #PIPEELBOW #PIPE REDUCER #INDUSTRYFLANGE

Email: admin@jsfittings.com

Whats App: 008618003119682