Get Free Samples

“We’re thrilled to have you here! Seize this opportunity to submit your inquiry, and we would be more than happy to welcome you to our factory.

Experience first-hand the meticulousness and dedication that goes into creating each of our high-quality pipe flanges and butt-weld pipe fittings.

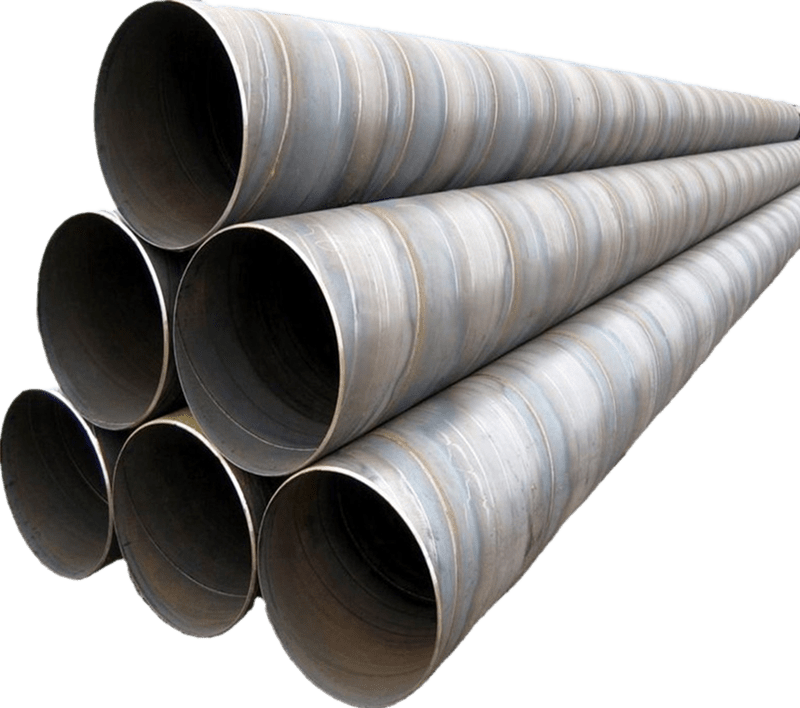

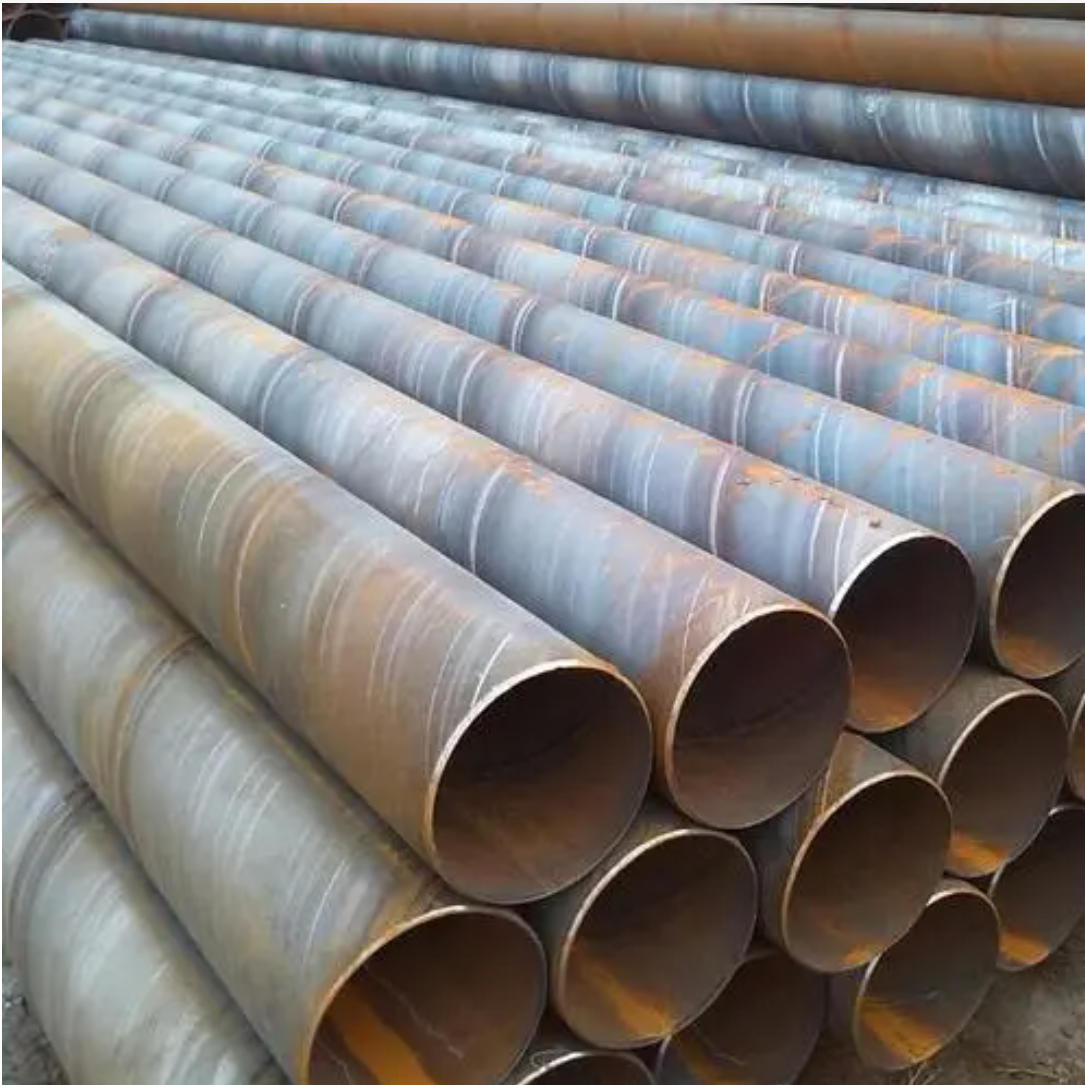

Spiral Submerged Arc Pipe

Meta Description: Get superior quality and performance with JS FITTINGS’ Spiral Submerged Arc Pipe. Made of the highest grade carbon steel, alloy steel, seamless pipe, ERW pipe, SSAW pipe and LSAW pipe for maximum strength and reliability. Find out why so many professionals trust our pipes today!

Product Features:

More

INFORMATION

SSAW welded pipes are manufactured from steel plates that are cut into strips, shaped by a series of forming rolls, and welded together. The SSAW pipe is formed by rolling a coiled steel strip into an elliptical shape and welding the ends together to form a spiral seam. This method allows for more flexibility when manufacturing large-diameter pipes, as it eliminates many of the constraints. Chemical Analysis and Mechanical Properties of SSAW Steel Pipes the production process of SSAW STEEL PIPE package and loading of ssaw steel pipesDescription of SSAW Steel Pipes

Specification of SSAW Steel Pipes

Standard

Grade

Chemical Composition(max)%

Mechanical Properties(min)

C

Si

Mn

P

S

Tensile Strength(Mpa)

Yield Strength(Mpa)

API 5CT

h40

–

–

–

–

0.030

417

417

J55

–

–

–

–

0.030

517

517

K55

–

–

–

–

0.300

655

655

API 5L PSL1

A

0.22

–

0.90

0.030

0.030

335

335

B

0.26

–

1.20

0.030

0.030

415

415

X42

0.26

–

1.30

0.030

0.030

415

415

X46

0.26

–

1.40

0.030

0.030

435

435

X52

0.26

–

1.40

0.030

0.030

460

460

X56

0.26

–

1.40

0.030

0.030

490

490

X60

0.26

–

1.40

0.030

0.030

520

520

X65

0.26

–

1.45

0.030

0.030

535

535

X70

0.26

–

1.65

0.030

0.030

570

570

API 5L PSL2

B

0.22

0.45

1.20

0.025

0.015

415

415

X42

0.22

0.45

1.30

0.025

0.015

415

415

X46

0.22

0.45

1.40

0.025

0.015

435

435

X52

0.22

0.45

1.40

0.025

0.015

460

460

X56

0.22

0.45

1.40

0.025

0.015

490

490

X60

0.12

0.45

1.60

0.025

0.015

520

520

X65

0.12

0.45

1.60

0.025

0.015

535

535

X70

0.12

0.45

1.70

0.025

0.015

570

570

X80

0.12

0.45

1.85

0.025

0.015

625

625

ASTM A53

A

0.25

0.10

0.95

0.050

0.045

330

330

B

0.30

0.10

1.20

0.050

0.045

415

415

ASTM A252

1

–

–

–

0.050

–

345

345

2

–

–

–

0.050

–

414

414

3

–

–

–

0.050

–

455

455

EN10217-1

P195TR1

0.13

0.35

0.70

0.025

0.020

320

320

P195TR2

0.13

0.35

0.70

0.025

0.020

320

320

P235TR1

0.16

0.35

1.20

0.025

0.020

360

360

P235TR2

0.16

0.35

1.20

0.025

0.020

360

360

P265TR1

0.20

0.40

1.40

0.025

0.020

410

410

P265TR2

0.20

0.40

1.40

0.025

0.020

410

410

EN10217-2

P195GH

0.13

0.35

0.70

0.025

0.020

320

320

P235GH

0.16

0.35

1.20

0.025

0.020

360

360

P265GH

0.20

0.40

1.40

0.025

0.020

410

410

EN10217-5

P235GH

0.16

0.35

1.20

0.025

0.020

360

360

P265GH

0.20

0.40

1.40

0.025

0.020

410

410

EN10219-1

S235JRH

0.17

–

1.40

0.040

0.040

360

360

S275JOH

0.20

–

1.50

0.035

0.035

410

410

S275J2H

0.20

–

1.50

0.030

0.030

410

410

S355JOH

0.22

0.55

1.60

0.035

0.035

470

470

S355J2H

0.22

0.55

1.60

0.030

0.030

470

470

S355K2H

0.22

0.55

1.60

0.030

0.030

470

470

Standard and Classification of SSAW steel pipes

Classification

Standard

Main Products

Steel Pipe for Fluid Service

GB/T 14291

Welded pipe for mine fluid service

GB/T 3091

Welded pipe for low-pressure fluid service

SY/T 5037

Spirally submerged arc welded steel pipe for pipelines for low-pressure fluid service

ASTM A53

Black and hot-dipped galvanized welded and seamless steel pipe

BS EN10217-2

Welded steel tubes for pressure purposes – delivery technical conditions – part2: Electric welded non-alloy and alloy steel tubes with specified elevated temperature properties

BS EN10217-5

Welded steel tubes for pressure purposes – delivery technical conditions – part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties

Steel Pipe for Ordinary Structure

GB/T 13793

Longitudinally electric resistance welded steel pipe

SY/T 5040

Spirally submerged arc-welded steel pipe piles

ASTM A252

Welded and seamless steel pipe piles

BS EN10219-1

Cold-formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivery conditions

BS EN10219-2

Cold-formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimensions and sectional properties

Line Pipe

GB/T 9711.1

Steel pipe for the pipeline transportation system of petroleum and natural gas industries(Class A steel pipe)

GB/T 9711.2

Steel pipe for the pipeline transportation system of petroleum and natural gas industries(Class B steel pipe)

API 5L PSL1/2

Line pipe

Casing

API 5CT

Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries

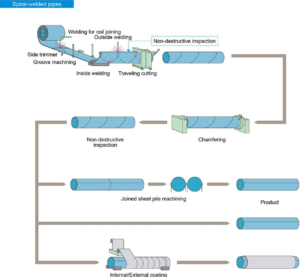

Production Process of SSAW steel pipes

Package and Loading

Whats App: +8618003119682

WeChat: JSFITTINGSCHINA

Email: admin@jsfittings.com