Get Free Samples

“We’re thrilled to have you here! Seize this opportunity to submit your inquiry, and we would be more than happy to welcome you to our factory.

Experience first-hand the meticulousness and dedication that goes into creating each of our high-quality pipe flanges and butt-weld pipe fittings.

LSAW A106 Steel Pipe

Space saving square design

Product Features:

Outside Diameter:Φ508mm- 1118mm (20″- 44″) Wall Thickness: 6.0-25.4mm 1/4″-1″ Length: 9-12.3m (30′- 40′)

More

INFORMATION

Longitudinal Submerged Arc Welded (LSAW) steel pipes are a type of high-performance steel pipe primarily used in heavy-duty industries like oil and gas transportation. They are produced by bending and welding steel plates, resulting in a pipe with a single longitudinal seam. LSAW pipes are known for their large diameter, thick wall, high-pressure resistance, and strong structural integrity, making them suitable for long-distance pipelines and underwater services. Despite being more labor-intensive and costly than other pipe types, their strength and durability make them an invaluable asset in demanding conditions. O.D. W.T. Length(m) Inch mm Min.Yield Strength(Mpa) Inch mm 245(B) 290(X42) 360(X52) 415(X60) 450(X65) 485(X70) 555(X80) 16 406 6.0-14.0 6.0-13.0 6.0-12.0 6.0-11.0 6.0-10.5 6.0-10.0 6.0-9.0 6.0-12.3 18 457 6.0-15.0 6.0-14.0 6.0-13.0 6.0-12.0 6.0-11.5 6.0-11.0 6.0-10.0 6.0-12.3 20 508 6.0-16.0 6.0-15.0 6.0-14.0 6.0-13.0 6.0-12.5 6.0-12.0 6.0-11.0 6.0-12.3 22 559 6.0-17.0 6.0-16.0 6.0-15.0 6.0-14.0 6.0-13.5 6.0-13.0 6.0-12.0 6.0-12.3 24 610 6.0-18.0 6.0-17.0 6.0-16.0 6.0-15.0 6.0-14.5 6.0-14.0 6.0-13.0 6.0-12.3 26 660 6.0-19.0 6.0-18.0 6.0-17.0 6.0-16.0 6.0-15.0 6.0-15.0 6.0-14.0 6.0-12.3 28 711 6.0-20.0 6.0-19.0 6.0-18.0 6.0-17.0 6.0-16.5 6.0-16.0 6.0-15.0 6.0-12.3 30 762 7.0-21.0 7.0-20.0 7.0-19.0 7.0-18.0 7.0-17.5 7.0-17.0 7.0-16.0 6.0-12.3 32 813 7.0-22.0 7.0-21.0 7.0-20.0 7.0-19.0 7.0-18.5 7.0-18.0 7.0-17.0 6.0-12.3 34 864 7.0-23.0 7.0-22.0 7.0-21.0 7.0-20.0 7.0-19.5 7.0-19.0 7.0-18.0 6.0-12.3 36 914 8.0-24.0 8.0-23.0 8.0-22.0 8.0-21.0 8.0-20.5 8.0-20.0 8.0-19.0 6.0-12.3 38 965 8.0-25.0 8.0-24.0 8.0-23.0 8.0-22.0 8.0-21.5 8.0-21.0 8.0-20.0 6.0-12.3 40 1016 8.0-26.0 8.0-25.0 8.0-24.0 8.0-23.0 8.0-22.5 8.0-22.0 8.0-21.0 6.0-12.3 42 1067 8.0-26.0 8.0-25.0 8.0-24.0 8.0-23.0 8.0-22.5 8.0-22.0 8.0-21.0 6.0-12.3 44 1118 9.0-27.0 9.0-26.0 9.0-24.5 9.0-23.5 9.0-22.8 9.0-22.0 9.0-21.0 6.0-12.3 46 1168 9.0-27.0 9.0-26.0 9.0-24.0 9.0-23.5 9.0-22.8 9.0-22.0 9.0-21.0 6.0-12.3 48 1219 9.0-28.0 9.0-27.0 9.0-25.4 9.0-24.0 9.0-23.5 9.0-23.0 9.0-22.0 6.0-12.3 52 1321 9.0-28.0 9.0-27.0 9.0-25.4 9.0-24.2 9.0-23.5 9.0-23.0 9.0-22.0 6.0-12.3 56 1422 10.0-29.0 10.0-28.0 10.0-26.0 10.0-24.5 10.0-23.8 10.0-23.0 10.0-22.0 6.0-12.3 60 1524 10.0-29.0 10.0-28.0 10.0-26.0 10.0-24.5 10.0-23.8 10.0-23.0 10.0-22.0 6.0-12.3 64 1626 10.0-30.0 10.0-29.0 10.0-27.0 10.0-25.4 10.0-24.8 10.0-24.0 10.0-23.0 6.0-12.3 68 1727 10.0-30.0 10.0-29.0 10.0-27.0 10.0-25.4 10.0-24.8 10.0-24.0 10.0-23.0 6.0-12.3 72 1829 10.0-30.0 10.0-29.0 10.0-27.0 10.0-25.4 10.0-24.8 10.0-24.0 10.0-23.0 6.0-12.3 Types Standard SY/T5040-2000 SY/T5037-2000 SY/T9711.1-1977 ASTM A252 AWWA C200-97 API 5L PSL1 Tube end OD deviation ±0.5%D ±0.5%D -0.79mm~+2.38mm <±0.1%T <±0.1%T ±1.6mm Wall thickness ±10.0%T D<508mm, ±12.5%T -8%T~+19.5%T <-12.5%T -8%T~+19.5%T 5.0mm<t<15.0mm,></t<15.0mm,> D>508mm, ±10.0%T T≥15.0mm, ±1.5mm JS FITTINGS has several third-party approvals for its manufacturing process as well as customer approvals. Destructive & non-destructive testing (In assuring the quality of our products, our own in-house testing facilities play an important role. Our laboratory is well equipped to perform a wide variety of both destructive and non-destructive quality tests.)Description of LSAW Steel Pipes

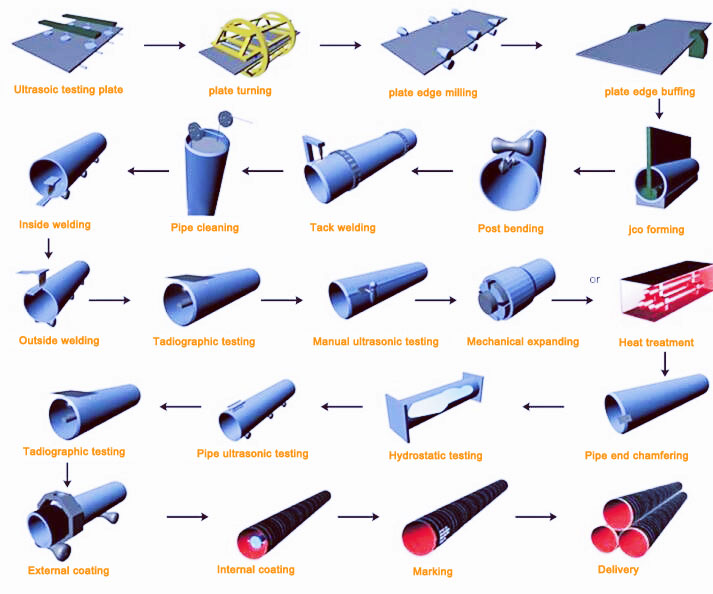

Production Process of LSAW Steel Pipes

Specification&Standard

Tolerance of Outside Diameter and Wall Thickness

QUALITY CONTROL

Destructive testing includes

tensile tests

Non-destructive testing includes

eddy current testing

impact tests

x-ray testing

bend tests

hydro testing

hardness tests

ultrasonic testing

intercrystalline corrosion test

positive material identification testing

pitting corrosion test

metallurgical tests

Whats App: +8618003119682

WeChat: JSFITTINGSCHINA

Email: admin@jsfittings.com

The message was sent successfully.

We will contact you within 2 hours, if you are urgent, please add our official

Whats App: 008618003119682 or Wechat: JSFITTINGSCHINA.

Hope we have a stable cooperation relationship in the future.